Electrical System

Check the wiring and connections.

The electrical system’s job is to carry voltage from one place to another. If the voltage can’t make the journey, or if it’s diminished when it gets there, the receiving device will not function properly, if at all. The goal is to have as much voltage (or electrical energy) arrive at Point B as left Point A. As electricity passes through a device, some parasitic loss is normal. However, corrosion impedes electricity’s ability to travel, which can cause significant voltage loss or intermittent voltage. Either can wreck the good times, but with simple visual inspections and physical actions these scenarios can usually be avoided.

The electrical system’s job is to carry voltage from one place to another. If the voltage can’t make the journey, or if it’s diminished when it gets there, the receiving device will not function properly, if at all. The goal is to have as much voltage (or electrical energy) arrive at Point B as left Point A. As electricity passes through a device, some parasitic loss is normal. However, corrosion impedes electricity’s ability to travel, which can cause significant voltage loss or intermittent voltage. Either can wreck the good times, but with simple visual inspections and physical actions these scenarios can usually be avoided.

Some electrical corrosion can be easy to see, such as corrosion on battery posts or electrical panel connections. But some damage can be more difficult to see, such as internal corrosion that has rotted some or all of the individual strands inside a wire’s cover. You can use an ohmmeter to check electrical connections and wires for excessive resistance. There should be no more than 0.1-0.2 ohm resistance between electrical connectors on each end of a wire. Any more than that and you should investigate further.

Some electrical corrosion can be easy to see, such as corrosion on battery posts or electrical panel connections. But some damage can be more difficult to see, such as internal corrosion that has rotted some or all of the individual strands inside a wire’s cover. You can use an ohmmeter to check electrical connections and wires for excessive resistance. There should be no more than 0.1-0.2 ohm resistance between electrical connectors on each end of a wire. Any more than that and you should investigate further.

Steve Pennaz on battery care

Don’t forget the batteries.

Make sure to use the right size and type recommended in your owner’s or service manual (see chart on next page for general specifications). If there’s any question about a battery’s performance, have it load tested. Any auto parts store can do this for you, or you can do it yourself with the right equipment.

Caution: Make sure that there are no fuel fumes present when making, breaking, or checking battery connections and condition. Give the area the “sniff test” to check for fumes. If in an enclosed area, run the blower or thoroughly air out the space, or take the battery outside to test it. Please plan and protect accordingly.

All battery cable connections must be clean, tight and use hex nuts and lock washers (not old- fashioned wing nuts). Loose connections can cause frustrating intermittent issues or a full-time “no run” condition. A dirty or corroded connection can impede electricity’s ability to travel, and a battery terminal connection may be corroded, yet appear clean. To avoid any doubt, always remove the terminal connection and clean both sides of the connecting materials down to bare, shiny metal, then re-install and tighten the connection properly. For regular maintenance, use Yamalube® Battery Terminal Cleaner & Protector. Simply spray it on and watch for the foam to change color, indicating that the corrosion (acid) has been neutralized. It then dries into a thin, waxy film, preventing the build-up of additional corrosion.

Consider “house batteries.”

Consider “house batteries” to power accessories. Most large Yamaha outboards (150hp and up) have separate battery isolator/charging leads specifically for this purpose. The outboard’s Dual Charge Monitoring System, with proper wiring, will first send charging voltage from the stator to the starting battery/batteries to help keep the voltage up and ready to go. Once fully charged, the outboard will automatically “switch” the charge to the house battery/batteries.

Check the electrical connections.

Check the electrical connections.

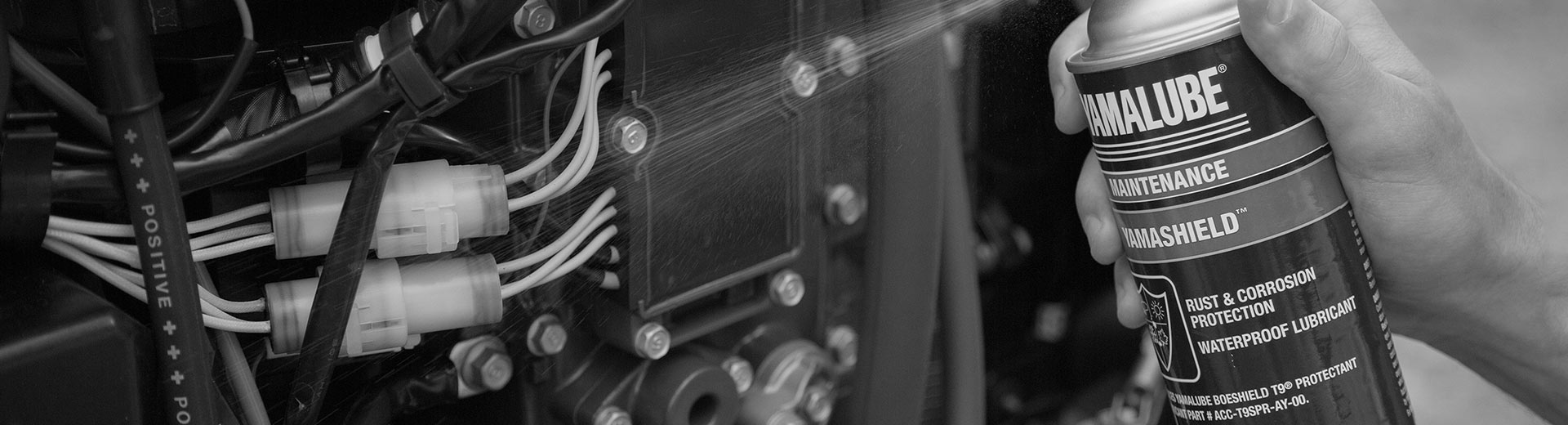

Corrosion often occurs where wires meet. Visually check electrical blocks under the dash and/or in the bilge. Also, check any connections on gauges or add-on electrical equipment like battery switches, plotters, or fish-finders. Wiggle wires and connections to check for looseness. If either is found, disconnect and clean the connection with emery cloth or fine-grit sand paper, then re-install and tighten properly. Finally, spray all electrical connections with a product like Yamashield,TM which puts down an anti-corrosive layer and leaves behind a protective film that helps prevent corrosion going forward.

Don’t spare the spray.

If you haven’t already sprayed connections with Yamashield or Yamalube® Silicone Protectant & Lubricant, remove the outboard cowling and liberally spray the entire powerhead. Not only will it help prevent corrosion, but it will help keep rubber parts (like your cowling seal) supple and able to do their job effectively.

If you haven’t already sprayed connections with Yamashield or Yamalube® Silicone Protectant & Lubricant, remove the outboard cowling and liberally spray the entire powerhead. Not only will it help prevent corrosion, but it will help keep rubber parts (like your cowling seal) supple and able to do their job effectively.

Tip: Do not spray silicone on any oxygen (O2) sensors that your outboard may have.

We’ve got the goods.

We’ve got the goods.

Yamaha offers a complete range of electrical system care products, including original- equipment NGK® spark plugs, Yamalube Yamashield Protectant and Lubricant, Yamalube Battery Terminal Cleaner & Protector, Yamalube Silicone Protectant & Lubricant, and Yamalube Contact Cleaner. They’re the best you can get for your outboard, and they’re all available through your local authorized Yamaha Marine dealer.

| YAMAHA US/CA MODELS | CHARGING VOLTS | UNIT | SPECIFICATIONS | |

| MIN | MAX | |||

| F8A | 15.0V | CCA/SAE | 245 A | 433 A |

| F9.9/T9.9 | MCA/ABYC | 323 A | 520 A | |

| F15/F20 | RC/SAE | 52 MIN | NA | |

| F25/T25 | ||||

| F30/F40 | 15.0V | |||

| F50/T50/F60/T60/F70 | CCA/SAE | 380 A | 1150 A | |

| F75/F90 | MCA/ABYC | 502 A | 1370 A | |

| F/LF115 | RC/SAE | 124 min | NA | |

| VF115 | ||||

| F/LF150 | 14.5V | CCA/SAE | 512 A | 1150 A |

| 3.3L F/LF200 | MCA/ABYC | 675 A | 1370 A | |

| 3.3L F/LF225 | RC/SAE | 124 min | NA | |

| 3.3L F/L250 | ||||

| 2.8L VF150, F175, F/LF200 | 14.5V | |||

| 4.2L VF200/225/250 | CCA/SAE | 680 A | 1150 A | |

| 4.2L F/LF225 | MCA/ABYC | 770 A | 1370 A | |

| 4.2L F/LF250 | RC/SAE | 160 min | NA | |

| 4.2L F/LF300 | ||||

| F/LF350 | 14.7V | CCA/SAE | 700 A | 1150 A |

| MCA/ABYC | 900 A | 1370 A | ||

| RC/SAE | 160 min | NA | ||

| HPDI | 14.5V | CCA/SAE | 512 A | 690 A |

| MCA/ABYC | 675 A | 840 A | ||

| RC/SAE | 182 min | NA | ||